AERO-S Manual

Version 1.1

Edition 0.1/25 August 2023

Farhat Research Group (FRG)

Stanford University

AERO-S

1 INTRODUCTION

This section compiles basic information on how to prepare an input data

for a finite element analysis using the AERO-S code, and how to run this code.

The input data consists of command macros, clustered numerical data, and

comment lines. Each data cluster is preceded by a command statement.

The following rules of thumb are suggested:

| 1 | The users are allowed to have as many comment lines as they wish,

as long as the first column of each line starts with * (see COMMENTS).

|

| 2 | The subsequent data clusters may appear in any

order. The command statement preceding each cluster may be in lower,

upper, or mixed characters.

|

| 3 | The data in each cluster are free format.

|

| 4 | Only the first four letters of a command need to be specified unless otherwise noted.

|

Any segment of a AERO-S input file — for example, the data corresponding to any command macro, or a command macro

and its data, or any number of input lines — can be replaced by a statement of the form

INCLUDE filename (or "filename")

|

where filename is the name of the file containing the information. "filename" can contain a path or can be replaced by

<filename> in which case the path is that of the environment variable \$FEM\_INCLUDE. Furthermore, the included file filename can be compressed

by gzip, bzip2, or zip.

Throughout this User's Reference Manual, the *S* symbol is used to designate a command that is distributed

according to a given mesh partition when SOWER is applied to AERO-S's standard

ASCII Input Command Data file in order to decompose it into binary files for (parallel) distributed I/O

(see SOWER's User's Reference Manual). A change in the data following any command designated by

this symbol requires re-executing SOWER.

AERO-S can be executed in serial or parallel mode. However, if the requested finite element analysis requires an equation solver, AERO-S runs in parallel mode on a given parallel architecture only

if the chosen equation solver (see STATICS) can

be executed in parallel mode on that parallel architecture. In the

latter case, performing the core finite element analysis — in addition

to the solution of the system(s)

of equations — in parallel using MPI and/or OpenMP requires

partitioning the finite element mesh using the DECOMPOSE command. If on the other hand the requested finite element analysis does not require an equation

solver, AERO-S can be executed in parallel mode on either a

shared or distributed memory system as long as the finite element mesh

is partitioned using the DECOMPOSE command.

The command line for executing AERO-S in serial mode is

aeros

| [-d <decomposition_pathandfilename>] | (Specifies a decomposition file).

|

| [-v <verbose_frequency>] | (Turns on verbose and specifies frequency of printing on screen the FETI iteration count and subspace iteration count).

|

| [-c] | (Outputs contact status on screen (FETI solver)).

|

| [-t] | (Converts input file to XPost format).

|

| [-T] | (Converts input file to XPost format after removing all numbering gaps).

|

| [-m] | (Converts input file to XPost format after gathering each material in a separate element set).

|

| [-M] | (Converts input file to XPost format after removing all numbering gaps and gathering each material in a separate element set).

|

| [-P] | (Generates automatically XPost patterns for the

various XPost element sets. This option is useful only

in conjunction with the -m and -M options

which can generate multiple XPost element sets. Also,

automatically generates a global element set).

|

| <filename.aeros.aicdf> | (AERO-S ASCII Input Command Data file containing the finite element structural model and analysis commands).

|

|

The command line for executing AERO-S in parallel mode on a shared memory system using OpenMP and number_of_threads threads is

aeros -n number_of_threads

| [-d <decomposition_pathandfilename>] | (Specifies a decomposition file).

|

| [-v <verbose_frequency>] | (Turns on verbose and specifies frequency

of printing on screen the FETI iteration count

and subspace iteration count).

|

| [-c] | (Outputs contact status on screen (FETI solver)).

|

| [-t] | (Converts input file to XPost format).

|

| [-T] | (Converts input file to XPost after removing all numbering gaps).

|

| [-m] | (Converts input file to XPost format after gathering each material in a separate element set).

|

| [-M] | (Converts input file to XPost format after removing all numbering gaps and gathering each material in a separate element set).

|

| [-P] | (Generates automatically XPost patterns for the

various XPost element sets. This option is useful only

in conjunction with the -m and -M options

which can generate multiple XPost element sets. Also,

automatically generates a global element set).

|

| <filename.aeros.aicdf> | (AERO-S ASCII Input Command Data file containing the finite element

structural model and analysis commands).

|

The command line for executing AERO-S in parallel mode on a distributed system using MPI with number_of_MPI_processes MPI processes [and number_of_threads_within_an_MPI_process threads within an MPI process] is

mpirun -np number_of_MPI_processes aeros -n number_of_threads_within_an_MPI_process

| [-d <decomposition_pathandfilename>] | (Specifies a decomposition file).

|

| [-v <verbose_frequency>] | (Turns on verbose and specifies frequency

of printing on screen the FETI iteration count

and subspace iteration count).

|

| [-c] | (Outputs contact status on screen (FETI solver)).

|

| [-t] | (Converts input file to XPost format).

|

| [-T] | (Converts input file to XPost after removing all numbering gaps).

|

| [-m] | (Converts input file to XPost format after gathering each material in a separate element set).

|

| [-M] | (Converts input file to XPost format after removing all numbering gaps and gathering each material in a separate element set).

|

| [-P] | (Generates automatically XPost patterns for the

various XPost element sets. This option is useful only

in conjunction with the -m and -M options

which can generate multiple XPost element sets. Also,

automatically generates a global element set).

|

| <filename.aeros.aicdf> | (AERO-S ASCII Input Command Data file containing the finite element structural model and analysis commands).

|

2 INSTALLATION

The installation of AERO-S on a given computing system requires the availability on that system of the following tools:

C++ compiler g++ | Version 4.1.2 or higher.

|

Fortran compiler gfortran | Version 4.1.2 or higher.

|

Flex utility | Version 2.5 or higher. Flex is a lexical analyser required for building the parser of AERO-S's input command data file.

|

Bison utility | Version 2.3 or higher. Bison is a parser generator required for building the parser of AERO-S's input command data file.

|

CMake utility | Version 2.6 or higher. CMake is a cross-platform open-source build system.

It is comparable to the Unix Make program in that the build process is ultimately controlled

by configuration files (CMakeLists.txt). However unlike Make, it does not directly build the final

software but instead generates standard build files such as makefiles for Unix and projects/workspaces for Windows

Visual C++. The CMake version 2.6 utility can be obtained from http://www.cmake.org.

(Note: a “README.cmake” file discussing details on cmake options for code configuration and installation is

available in the directory containing the source code of AERO-S).

|

and following libraries:

BLAS library | BLAS is a set of Basic Linear Algebra Subprograms required by various

operations performed in AERO-S.

|

LAPACK library | LAPACK is a high-performance Linear Algebra PACKage with advanced solvers.

|

MPI library openmpi | Version 1.2.6 or higher. Open MPI is a high-performance implementation of the Message Passing Interface (MPI) required

for performing interprocessor communication, among others. More specifically, AERO-S requires an

MPI-2 implementation such as the one provided by the Open MPI project.

|

OpenMP API | Open

Multi-Processing is an Application Programming Interface (API) that

supports

multi-platform shared memory multiprocessing programming in C, C++ and

Fortran on many architectures, including Unix. As an option,

AERO-F can be compiled with OpenMP to enable multi-threaded execution.

|

In addition, the following optional libraries extend the capabilities of AERO-S:

SPOOLES library | SPOOLES is a library for solving sparse real and complex linear systems of equations

with a sparse direct solver, written in the C language using object oriented design.

|

MUMPS library | MUMPS

is a library for solving sparse real and complex linear systems of

equations with a multifrontal massively parallel sparse direct solver.

|

SUPERLU library | SUPERLU is a general purpose library for the direct solution of large sparse nonsymmetric systems on high performance machines.

|

ARPACK library | ARPACK is the Arnoldi PACKage for the solution of large-scale symmetric, nonsymmetric, and generalized eigenproblems.

|

ScaLAPACK library | ScaLAPACK

is also known as the Scalable LAPACK. This library includes a subset of

LAPACK routines redesigned for distributed memory MIMD parallel

computers.

|

BLACS library | BLACS

(Basic Linear Algebra Communication Subprograms) is a linear algebra

oriented message passing interface designed for linear algebra.

|

PARPACK library | PARPACK is the parallel version of ARPACK used by AERO-S's parallel eigensolver.

|

METIS library | METIS is a library of graph manipulation routines that can be used by AERO-S for reordering of a sparse matrix to reduce the number of fill-in entries created during

factorization.

|

Zoltan library | The Zoltan library includes among other things a suite of dynamic load-balancing and parallel partitioning tools that are used by AERO-S for parallel proximity searches.

|

Eigen3 library | Eigen3

is a versatile C++ template library for linear algebra (vectors,

matrices, and related algorithms (see http://eigen.tuxfamily.org)).

|

To install AERO-S, follow the procedure specified below:

The successful completion of the procedure described above leads to the creation in the bin/ directory of AERO-S's executable aeros.

3 ACOUSTIC TIME-DOMAIN ARTIFICIAL BOUNDARY *S*

|

Command Statement: ATDARB

|

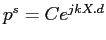

The ATDARB command statement is used to specify the artificial boundary  on which

an Antoine absorbing condition is to be applied in the time domain, and the order of this absorbing boundary condition.

The input format is given below.

on which

an Antoine absorbing condition is to be applied in the time domain, and the order of this absorbing boundary condition.

The input format is given below.

FACE FACE_TYPE CONNECTIVITY_NODES

|

ORDER

| Order of Antoine's absorbing boundary condition in the time domain (real). Currently supported values are 0 and 1.

|

FACE

| Face (or edge in two dimensions)

identification number whose type and connectivity are to be specified

(integer). In practice, this identification number is ignored by AERO-S.

|

FACE_TYPE |

|

| 1

| 2-node line segment. To be used with two-dimensional linear elements.

|

| 2

| 3-node line segment. To be used with two-dimensional quadratic elements.

|

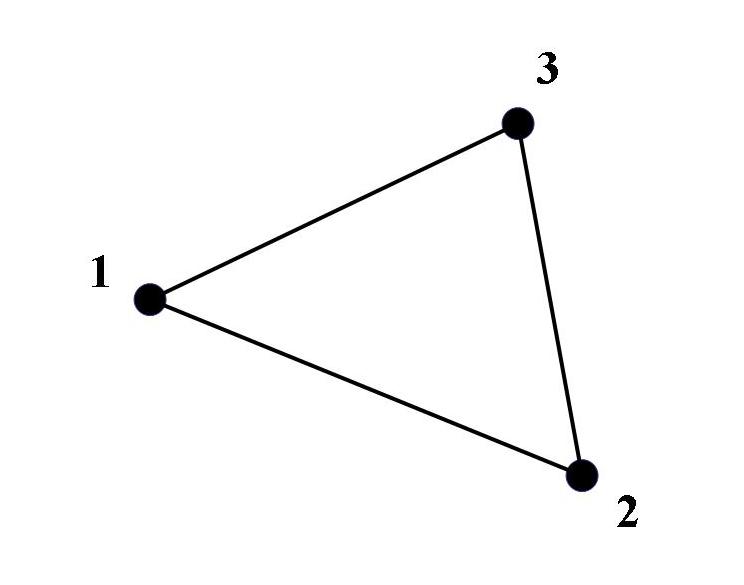

| 3

| 3-node triangular face. To be used with three-dimensional linear tetrahedral element.

|

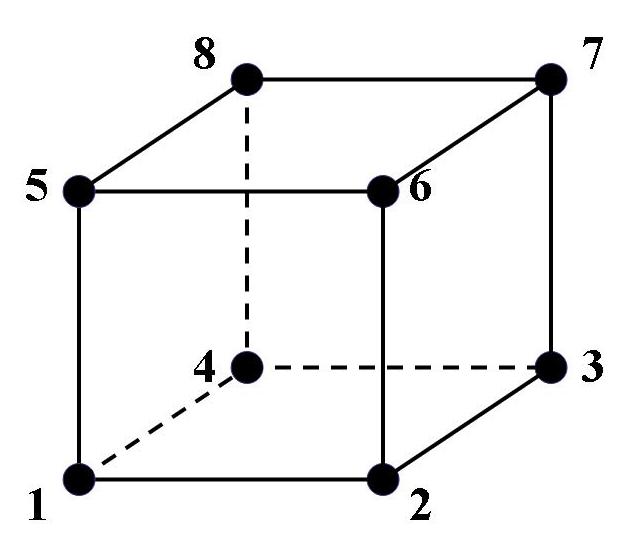

| 4

| 4-node quad face. To be used with three-dimensional linear hexahedral element.

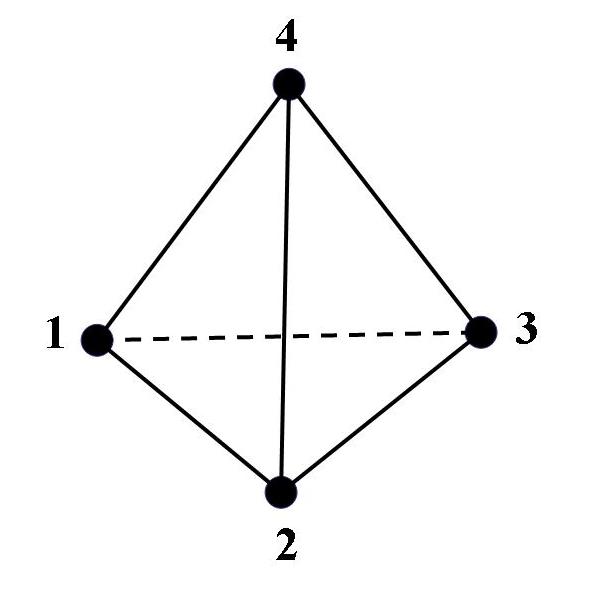

|

| 6

| 6-node triangular face. To be used with three-dimensional quadratic tetrahedral element.

|

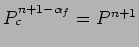

| 10

|  -node arbitrarily higher-order quad face where -node arbitrarily higher-order quad face where  is the number of nodes on an edge of this face. To be used with element type 95. is the number of nodes on an edge of this face. To be used with element type 95.

|

| 11

| arbitrarily higher-order triangular face.

|

| 12

| arbitrarily higher-order line segment.

|

| 13

| edge of a full isoparametric triangular element where the nodes are numbered linearly along it.

|

| 14

|  -node arbitrarily higher-order (spectral) quad face where -node arbitrarily higher-order (spectral) quad face where  is the number of nodes on an edge of this face. To be used with spectral element type 105. is the number of nodes on an edge of this face. To be used with spectral element type 105.

|

CONNECTIVITY_NODES

| These should be listed in a stacked

fashion on a single line, and numbered clockwise (when looking from

infinity in three dimensions).

|

4 ACOUSTIC TIME-DOMAIN DIRICHLET BOUNDARY CONDITIONS *S*

|

Command Statement: ATDDIR

|

The ATDDIR command statement is used to specify nodal Dirichlet boundary conditions

for a time-domain acoustic scattering problem. The input format is given below.

NODE#

| Node number where the Dirichlet boundary condition is specified (integer).

|

VALUE

| Value of the specified boundary condition (real).

|

5 ACOUSTIC TIME-DOMAIN DISTRIBUTED NEUMANN BOUNDARY CONDITION *S*

|

Command Statement: ATDDNB

|

The ATDDNB command statement is used to specify the surface of a scatterer on which a

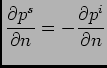

distributed Neumann boundary condition of the form  is applied in a time-domain acoustic computation, and the value of the constant c.

is applied in a time-domain acoustic computation, and the value of the constant c.

The input format of this command is given below.

FACE FACE_TYPE CONNECTIVITY_NODES

|

CONSTANT |

Value of the constant c (real).

|

FACE

| Face (or edge in two dimensions)

identification number whose type and connectivity are to be specified

(integer). In practice, this identification number is ignored by AERO-S.

|

FACE_TYPE |

|

| 1

| 2-node line segment. To be used with two-dimensional linear elements.

|

| 2

| 3-node line segment. To be used with two-dimensional quadratic elements.

|

| 3

| 3-node triangular face. To be used with three-dimensional linear tetrahedral element.

|

| 4

| 4-node quad face. To be used with three-dimensional linear hexahedral element.

|

| 6

| 6-node triangular face. To be used with three-dimensional quadratic tetrahedral element.

|

| 10

|  -node arbitrarily higher-order quad face where -node arbitrarily higher-order quad face where  is the number of nodes on an edge of this face. To be used with element type 95.^M is the number of nodes on an edge of this face. To be used with element type 95.^M

|

| 11

| arbitrarily higher-order triangular face.

|

| 12

| arbitrarily higher-order line segment.

|

| 13

| edge of a full isoparametric triangular element where the nodes are numbered linearly along it.

|

| 14

|  -node arbitrarily higher-order (spectral) quad face where -node arbitrarily higher-order (spectral) quad face where  is the number of nodes on an edge of this face. To be used with spectral element type 105. is the number of nodes on an edge of this face. To be used with spectral element type 105.

|

CONNECTIVITY_NODES

| These should be listed in a stacked fashion on a single line, and numbered clockwise (when looking from infinity in three

dimensions).

|

6 ACOUSTIC TIME-DOMAIN NEUMANN BOUNDARY CONDITIONS *S*

|

Command Statement: ATDNEU

|

The ATDNEU command statement is used to specify the nodal Neumann boundary conditions

for a time-domain acoustic scattering problem. The input format is given below.

NODE#

| Node number where the Neumann boundary condition is specified (integer).

|

VALUE

| Value of the specified boundary condition (real).

|

7 ACOUSTIC TIME-DOMAIN ROBIN DISTRIBUTED BOUNDARY CONDITION *S*

|

Command Statement: ATDROB

|

The ATDROB command statement can be used to specify the surface of a scatterer on which a

distributed Robin boundary condition of the form  is applied in a time-domain acoustic

computation, and the three constants

is applied in a time-domain acoustic

computation, and the three constants  ,

,  , and

, and  .

.

The input format of this command is given below.

FACE FACE_TYPE CONNECTIVITY_NODES

|

| Non-zero constant premultiplying the normal derivative of the Robin boundary condition (real).

|

| Constant premultiplying the unknown of the Robin boundary condition (float).

|

| Constant right hand-side of the Robin boundary condition (float).

|

FACE

| Face (or edge in two dimensions)

identification number whose type and connectivity are to be specified

(integer). In practice, this identification number is ignored by AERO-S.

|

FACE_TYPE |

|

| 1

| 2-node line segment. To be used with two-dimensional linear elements.

|

| 2

| 3-node line segment. To be used with two-dimensional quadratic elements.

|

| 3

| 3-node triangular face. To be used with three-dimensional linear tetrahedral element.

|

| 4

| 4-node quad face. To be used with three-dimensional linear hexahedral element.

|

| 6

| 6-node triangular face. To be used with three-dimensional quadratic tetrahedral element.

|

| 10

|  -node arbitrarily higher-order quad face where -node arbitrarily higher-order quad face where  is the number of nodes on an edge of this face. To be used with element type 95.^M is the number of nodes on an edge of this face. To be used with element type 95.^M

|

| 11

| arbitrarily higher-order triangular face.

|

| 12

| arbitrarily higher-order line segment.

|

| 13

| edge of a full isoparametric triangular element where the nodes are numbered linearly along it.

|

| 14

|  -node arbitrarily higher-order (spectral) quad face where -node arbitrarily higher-order (spectral) quad face where  is the number of nodes on an edge of this face. To be used with spectral element type 105. is the number of nodes on an edge of this face. To be used with spectral element type 105.

|

CONNECTIVITY_NODES

| These should be listed in a

stacked fashion on a single line, and numbered clockwise (when looking

from infinity in three dimensions).

|

8 ACTUATORS *S*

|

Command Statement: ACTUATORS

|

The ACTUATORS command is used to prescribe at specified nodes and local degrees of freedom a time-variant source term

(for example, a force field for a structural model) using a user-defined subroutine, and request the solution

state at that node (for example, the displacement, velocity, and acceleration fields for a structural model). In this case,

the user has to write his/her own algorithm for specifying the prescribed source term within a subroutine named "control.C".

The SENSORS command must be used to pass to "control.C" the solution state at the nodes of interest (see SENSORS).

The user should grab the special makefile for this command which is located within the AERO-S.d/Control.d directory,

and use the LOAD command to activate this command.

For structural models, all prescribed forces and moments are interpreted by default as being of the axial type — that is,

as being defined in the fixed nodal degree of freedom reference frames (see NODES and NFRAMES).

However, if a node has rotational degrees of freedom, the user can

specify that the forces and/or moments prescribed at this node

are of the follower type — that is, they act in a direction that remains constant in the local frame attached to the node

where they are applied. This local frame coincides with the nodal degree of freedom reference frame

(see NODES and NFRAMES) in the undeformed configuration. In the deformed configuration, the orientation of

this local frame is defined by the rotation of the node to which it is attached. In other words, the specified

nodal force or moment "follows" in this case the rotation of the node to which it is applied.

An example input file using this command can be found in APPENDIX 1.

Note 1: By default, the nodal degree of freedom reference frames are the same as the global reference frame.

Note 2: For structural models, specifying a follower force or moment leads to an unsymmetric tangent "load" stiffness

matrix during a NONLINEAR analysis.

The syntax for invoking this option is given below.

NODE#

| Node number where an actuating force/moment is specified (integer).

|

DOF#

| Degree of freedom local number where an actuating force/moment is specified (integer).

|

TYPE

| For structural models, all specified nodal source terms are by default of the axial type. However, if this parameter

is set to FOLLOWER and the node NODE# has rotational degrees of freedom, the source term specified

at this node and degree of freedom DOF# is considered to be of the follower type (characters).

|

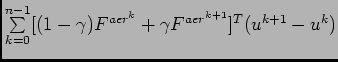

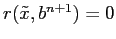

9 AEROELASTICITY

The AERO command statement can be used to perform any of the following instructions:

- Request that AERO-S sends to AERO-F one or several displacement fields of the structure.

- Indicate that AERO-S is to interact with AERO-F to compute a flow-induced

load and perform the corresponding static structural analysis, or perform a coupled static or dynamic aeroelastic simulation.

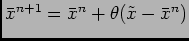

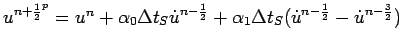

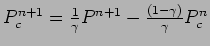

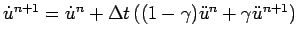

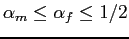

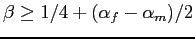

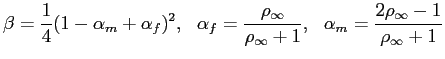

- Choose a staggered time-integration algorithm (ALGORITHM subcommand) and, if needed, a displacement predictor

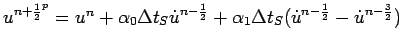

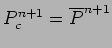

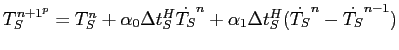

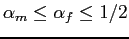

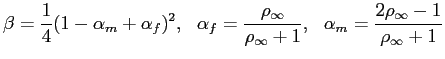

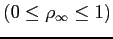

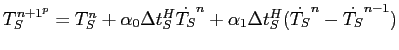

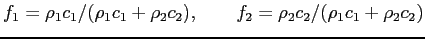

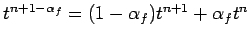

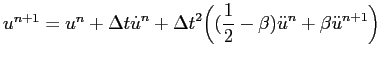

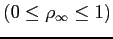

(ALGORITHM subcommand) defined by two coefficients  and

and  and the formula

and the formula

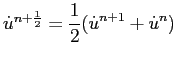

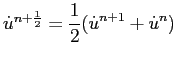

when the structural time-integrator is implicit, with

when the structural time-integrator is implicit, with  if

if A6 is the chosen time-integration algorithm and

otherwise, or

otherwise, or

when the structural time-integrator is explicit, to perform a static or dynamic aeroelastic simulation.

Here,  (

(  ) is the predicted displacement field at time-step

) is the predicted displacement field at time-step  (

(  ) and

) and  is the structural time-step size (or simply,

time-step) resulting from some settings of the DYNAMICS command.

It is relevant however only for dynamic simulations.

is the structural time-step size (or simply,

time-step) resulting from some settings of the DYNAMICS command.

It is relevant however only for dynamic simulations.

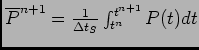

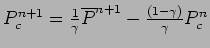

- Select an algorithm for computing the corrected pressure field  to be used in computing the aerodynamic forces acting

on the structure at time-step

to be used in computing the aerodynamic forces acting

on the structure at time-step  (

(PRESSURE subcommand) of a dynamic aeroelastic simulation.

- Specify the structure matcher file, when either the Arbitrary

Lagrangian/Eulerian (ALE) framework is chosen for performing a coupled

dynamic or static fluid-structure

simulation without element deletion, or the Embedded Boundary

Method (EBM) framework is used for this purpose and the embedded surface

is inputted to the flow solver AERO-F.

Note that the ALE fraework does not support element deletion, and the

EBM framework supports it only if the embedded discrete surface is

identical to the wet surface of the finite element structural model

and inputted under this command.

- Specify the discrete surface to be embedded in the fluid grid, when

the EBM framework is chosen for performing a coupled dynamic or static

fluid-structure

simulation with or without element deletion, if this surface is

identical to the wet surface of the finite element structural model and

defined using the same nodes of this model. Otherwise, provided

that the simulation is to be performed without element deletion, the

discrete surface to be embedded in the fluid grid should be inputted to AERO-F and the structure matcher file should be

specified under this command.

The purpose of the displacement predictor and that of the force

corrector are to compensate for the effects of time-lagging. More

specifically,

they improve the time-accuracy and numerical stability of the chosen

staggered solution algorithm by minimizing the lack of energy

conservation at the fluid-structure

interface. The theoretical, algorithmic, and practical aspects of both

of these “compensators” are described in

S. Piperno and C. Farhat, “Partitioned Procedures for the Transient Solution of Coupled Aeroelastic Problems - Part II:

Energy Transfer Analysis and Three-Dimensional Applications,” Computer Methods in Applied Mechanics and Engineering, Vol. 190,

pp. 3147-3170 (2001)

Before setting the values of  and

and  that complete the definition of the displacement predictor and choosing the force corrector,

the user should note that:

that complete the definition of the displacement predictor and choosing the force corrector,

the user should note that:

- Currently, the fluid code AERO-F can send to AERO-S at

either the pressure field at

either the pressure field at

,

,  , or the averaged pressure field

, or the averaged pressure field  .

Hence,

.

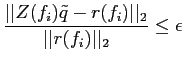

Hence,  can be set at least to either of these two values. Therefore, the purpose of the

can be set at least to either of these two values. Therefore, the purpose of the PRESSURE subcommand is to propose

additional choices for the corrected pressure field  . These can affect the order of time-accuracy of the chosen staggered

solution algorithm (see C. Farhat, G. van der Zee and P. Geuzaine,

“Provably Second-Order Time-Accurate Loosely-Coupled Solution Algorithms

for Transient

Nonlinear Computational Aeroelasticity,” Computer Methods in Applied

Mechanics and Engineering, Vol. 195, pp. 1973-2001 (2006)).

. These can affect the order of time-accuracy of the chosen staggered

solution algorithm (see C. Farhat, G. van der Zee and P. Geuzaine,

“Provably Second-Order Time-Accurate Loosely-Coupled Solution Algorithms

for Transient

Nonlinear Computational Aeroelasticity,” Computer Methods in Applied

Mechanics and Engineering, Vol. 195, pp. 1973-2001 (2006)).

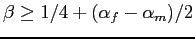

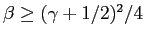

- The values of

and

and  that minimize the variation of energy exchanged at the

fluid-structure interface

and therefore improve time-accuracy and numerical stability of the

chosen staggered solution algorithm depend on the chosen fluid and

structure

time-integrators, the chosen force corrector, and the selected staggered

solution algorithm itself.

that minimize the variation of energy exchanged at the

fluid-structure interface

and therefore improve time-accuracy and numerical stability of the

chosen staggered solution algorithm depend on the chosen fluid and

structure

time-integrators, the chosen force corrector, and the selected staggered

solution algorithm itself.

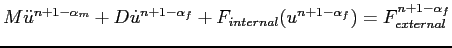

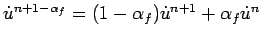

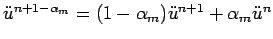

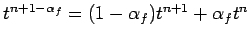

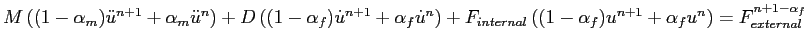

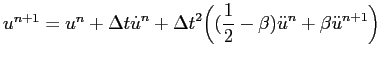

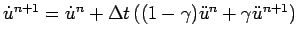

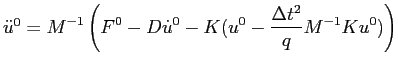

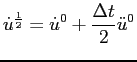

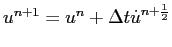

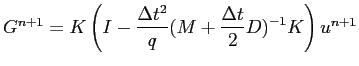

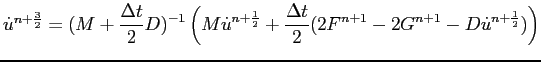

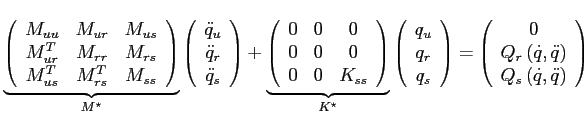

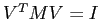

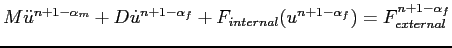

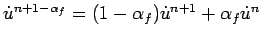

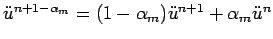

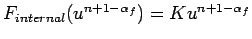

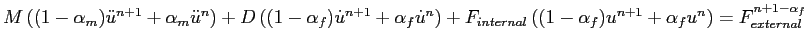

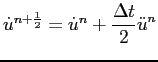

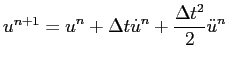

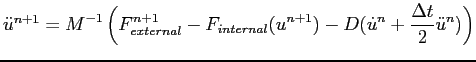

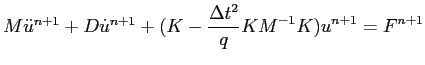

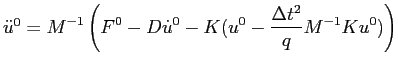

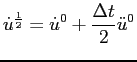

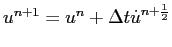

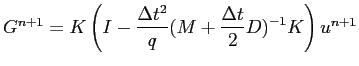

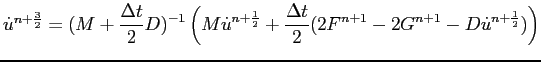

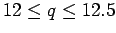

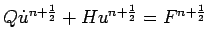

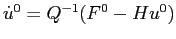

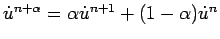

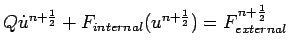

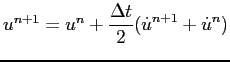

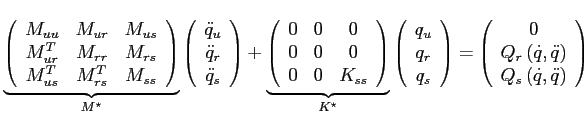

- When the Generalized

method is used for time-integrating linear or nonlinear structural dynamics problems (see DYNAMICS), AERO-S solves the following equilibrium problem

method is used for time-integrating linear or nonlinear structural dynamics problems (see DYNAMICS), AERO-S solves the following equilibrium problem

- When the central difference method is used for time-integrating structural dynamics problems (see DYNAMICS), AERO-S solves the following equilibrium problem

Note 1: AERO-F offers two different computational frameworks for fluid-structure interaction: an ALE

framework, and an EBM framework. When a functional capability described below is meaningful, applicable, or supported

by only one of these two computational frameworks, its designating keyword is followed by [ALE]

in the case of the ALE computational framework, and by [EMB] in the case of EBM computational framework. When

this capability is applicable, meaningful, and supported by both computational frameworks, its designating keyword is not

followed by any symbol.

Note 2: The algorithms PP and MPP require the additional presence of DYNAMICS in the input file.

Note 3: The algorithm B0 requires the additional presence of QSTATICS in the input file. In this case,

Problem.Type in AERO-F should be set to SteadyAeroelastic.

Note 4: For a static aeroelastic analysis, A0, A4, A5, A6, B0 and C0 are irrelevant as

QSTATICS, which is also needed in this case, is equipped with its own staggered solution algorithm. However, for parsing

reasons, one of these staggered solution algorithms must be explicitly specified even if it will be ignored.

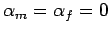

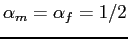

Note 5: The values of  and

and  derived in the paper by Piperno and Farhat mentioned above correspond to

the case where the structure is linear and time-integrated by the Newmark algorithm with

derived in the paper by Piperno and Farhat mentioned above correspond to

the case where the structure is linear and time-integrated by the Newmark algorithm with  and

and  .

For other structural time-integrator choices, that analysis needs to be redone for choosing the parameters of the command

.

For other structural time-integrator choices, that analysis needs to be redone for choosing the parameters of the command AERO.

Note 6: If an aeroelastic analysis is requested with all of the GEPS, IDISP6, and IDISPLACEMENTS commands present in the input file, AERO-S interprets

the IDISPLACEMENTS command and its content as the initialization of the incremental displacement field from the configuration  (see GEPS) to the configuration

(see GEPS) to the configuration  (see GEPS).

In this case, it sends to the fluid code at each time-step the sum of

the updated incremental displacement and the displacement inputted under

the IDISP6 command. Hence, this scenario is particularly suitable

for the case where the fluid code is started from a deformed CFD mesh. If on the other hand an aeroelastic analysis is requested

with only the

(see GEPS).

In this case, it sends to the fluid code at each time-step the sum of

the updated incremental displacement and the displacement inputted under

the IDISP6 command. Hence, this scenario is particularly suitable

for the case where the fluid code is started from a deformed CFD mesh. If on the other hand an aeroelastic analysis is requested

with only the GEPS and IDISP6 commands present in the input file, AERO-S

understands that the incremental displacement field is initialized to

zero. However, it communicates

in this case with the fluid code in a very special manner: at the first

time-step, it sends to the fluid code the initial value of the

incremental displacement field (which in this case is zero),

and at each subsequent time-step, the sum of the updated incremental

displacement and the displacement specified under the IDISP6 command. Hence, the latter scenario is particularly suitable

for the case where the fluid code is started from an undeformed CFD mesh.

The syntax for invoking this command is given below.

ALGORITHM |  |

| SUBCYCLING | n_subcycles |

| PRESSURE | |

| MATCHER | pathandfilename |

| EMBEDDED | embeddedsurfaceid |

|

|

ALGORITHM |

|

PP [ALE]

| This “Ping-Pong” algorithm sends the initial displacement of the structure, specified under either the IDISP6

command or the IDISPLACEMENTS (possibly equipped with the sub-command MODAL), to the fluid code which receives

it and deforms the CFD mesh accordingly (characters). For this purpose, the DYNAMICS command must also be present in

the AERO-S input file. After the send occurs, the structure code exits gracefully, the fluid code computes the

fluid mesh deformation associated with the specified structural displacement and outputs (if requested) the corresponding

position and/or displacement of the fluid mesh (characters).

|

MPP

| This “Multi-Ping-Pong” algorithm sends several initial displacements of the structure at a time — for example, modal

displacements — to the fluid code, which uses them to compute compatible fluid mesh deformations. The READMODE

command

must be used to input the initial displacements of interest — for

example, a set of eigenmodes. If the second format of that

command is used to specify the Reduced-Order Basis (ROB) to be

used to generate the initial displacements, the coefficient  of this command must be used to identify that ROB (see the field

of this command must be used to identify that ROB (see the field rob_idi in READMODE).

If a coefficient  is specified after is specified after MPP, the initial displacements are amplified by  before they are sent to the

fluid code. However, the fluid code scales back by before they are sent to the

fluid code. However, the fluid code scales back by  the corresponding fluid mesh displacements it computes before

saving them in an output file, in order to preserve the effect of

the mass normalization of the modal structural

displacements. The deformed fluid mesh configurations can then be

used to generate sources of excitations for the

construction of fluid POD bases and ROMs, or for linearized

(perturbation) flow simulations whose initial conditions involve

a (modal) position or velocity of the fluid surface mesh.

the corresponding fluid mesh displacements it computes before

saving them in an output file, in order to preserve the effect of

the mass normalization of the modal structural

displacements. The deformed fluid mesh configurations can then be

used to generate sources of excitations for the

construction of fluid POD bases and ROMs, or for linearized

(perturbation) flow simulations whose initial conditions involve

a (modal) position or velocity of the fluid surface mesh.

As for the “Ping-Pong” case, the DYNAMICS command

must also be present in the AERO-S input file, AERO-S exits gracefully after the send occurs,

the fluid code computes the fluid mesh deformation associated with the specified structural displacements and outputs

(if requested) the corresponding positions and/or displacements of the fluid mesh. In addition, for each inputted deformed

fluid mesh position, the fluid code outputs an identification tag — for example, the frequency of the corresponding input

structural mode in the case of modal displacements (characters).

|

A0

| This is the basic sequential staggered solution algorithm (characters). When fluid subcycling is effected, the same algorithm

has been referred to in the AIAA Paper 96-1388 by Farhat and co-workers as the A1

algorithm (characters).

It should not be used without a displacement predictor as it would

reduce the overall order of time-accuracy compared to that

intrinsic to the structural time-integrator. For the same reason,

it is also not recommended — and as a matter of fact not

available — when the structural time-integrator is explicit.

|

A4

| This is the basic staggered solution algorithm with fluid-structure inter-parallelism (characters). It has been referred to

as A2 in the AIAA Paper 96-1388 by Farhat and co-workers. When this algorithm is specified, AERO-F sends

to AERO-S  or or  rather than the corresponding pressure fields at rather than the corresponding pressure fields at  .

Currently, this algorithm is not available when an explicit structural time-integrator is chosen. .

Currently, this algorithm is not available when an explicit structural time-integrator is chosen.

|

A5

| This staggered solution algorithm also features inter-parallelism but offers a better accuracy than A4

when both

methods are used without a displacement predictor (characters).

Currently, this algorithm is not available when an explicit

structural time-integrator is chosen.

|

A6

| This staggered solution

algorithm has superior stability and accuracy properties. It is

recommended when the fluid is

time-advanced by an implicit time-integrator. It has been referred

to in most papers by Farhat and co-workers as the ISS

(Improved Serial Staggered algorithm) method (characters). It

delivers good accuracy without any displacement predictor. However,

it is provably second-order time-accurate when equipped with the

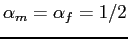

the displacement predictor defined by  and and  ,

the midpoint implementation of the Newmark time-integrator with ,

the midpoint implementation of the Newmark time-integrator with  and and  (see DYNAMICS),

and a second-order time-integrator for the discrete fluid problem. Also, this partitioned solution procedure prefers a non

time-averaged pressure field. Most importantly, it was designed to be used exclusively with the (see DYNAMICS),

and a second-order time-integrator for the discrete fluid problem. Also, this partitioned solution procedure prefers a non

time-averaged pressure field. Most importantly, it was designed to be used exclusively with the NONCOLLOCATED scheme of aerodynamic

force evaluation (see below) (characters). Currently, it does not support an explicit structural time-integrator.

|

B0

| This one-way coupled

steady-state aeroelastic algorithm sends the initial displacement of the

structure (if any) to the flow solver. After receiving it and updating

its mesh, AERO-F performs any requested flow simulation and sends to AERO-S upon completion the

flow-induced load. Then, AERO-S receives this load, performs a static analysis if requested, and finally outputs

any requested data (such as the computed flow-induced load, and/or resulting displacement, stress, and strain fields).

|

C0

| This staggered solution algorithm is designed for the case where the structural subsystem is time-integrated by

the explicit central difference method (see DYNAMICS),

and the fluid subsystem is time-integrated by either an

explicit or an implicit scheme. As shown in C. Farhat, A. Rallu,

K. Wang and T. Belytschko, “Robust and Provably

Second-Order Explicit-Explicit and Implicit-Explicit Staggered

Time-Integrators for Highly Nonlinear Fluid-Structure Interaction

Problems,” International Journal for Numerical Methods in

Engineering, (2010), it is genuinely second-order time-accurate

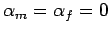

when equipped with the second-order displacement predictor

obtained by setting  and and  (see below), and a second (or higher)-order accurate explicit or

implicit ALE fluid time-integrator. Currently, this algorithm

supports only explicit structural time-integrators, and is the

only algorithm which supports element deletion in fluid-structure

simulations.

(see below), and a second (or higher)-order accurate explicit or

implicit ALE fluid time-integrator. Currently, this algorithm

supports only explicit structural time-integrators, and is the

only algorithm which supports element deletion in fluid-structure

simulations.

|

| When used with the MPP command, this coefficient can be specified to amplify the initial displacements to be sent

to the fluid code (however, as noted above, the fluid mesh displacements computed by the fluid code are scaled back by

before they are saved in an output file). In this case, the default value is 1. Otherwise, this coefficient

is part of the construction of a predictor for the position of the structure. For before they are saved in an output file). In this case, the default value is 1. Otherwise, this coefficient

is part of the construction of a predictor for the position of the structure. For  (and (and  ), no prediction is effected.

Setting ), no prediction is effected.

Setting  (and (and  ) generates a first-order prediction, and setting ) generates a first-order prediction, and setting  (and (and  generates

a second-order prediction. The optimal values of generates

a second-order prediction. The optimal values of  and and  depend on the specifics of the fluid and structure field

time-integrators (see the aforementioned paper on interface energy

conservation by Piperno and Farhat) (real). In this case, the default

value is 0.5

for algorithm

depend on the specifics of the fluid and structure field

time-integrators (see the aforementioned paper on interface energy

conservation by Piperno and Farhat) (real). In this case, the default

value is 0.5

for algorithm C0, and 0 for all other algorithms.

|

| When used with the MPP command, this coefficient is interepreted as an integer that identifies among the reduced-order bases read using the READMODE command (see there the

field rob_idi) that to be used with the algorithm MPP

(integer). Otherwise, this coefficient is interpreted as a real

coefficient that is part of the construction of a predictor

for the position of the structure (real) and therefore should be

used only as such (see above). In this case, its default value is  for algorithm for algorithm C0, and 0 for all other algorithms.

|

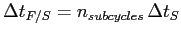

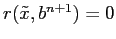

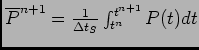

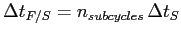

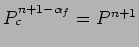

SUBCYCLING n_subcycles | This

pair of sub-command keyword (characters) and corresponding numerical

value (integer) specifies the structural subcycling factor, which

defines the coupling fluid-structure time-step size (or simply, time-step)  – that is, the time-interval during which structural and fluid

computations are performed without

any coupling, or equivalently, the time-interval between two

couplings of the fluid and structural sub-systems – as follows

– that is, the time-interval during which structural and fluid

computations are performed without

any coupling, or equivalently, the time-interval between two

couplings of the fluid and structural sub-systems – as follows

where  is the structural time-step resulting from some settings of the DYNAMICS command. Hence, is the structural time-step resulting from some settings of the DYNAMICS command. Hence, n_subcycles can also be described as the number of time-steps that the

structural analyzer performs per coupling fluid-structure time-step. The default value is 1.

|

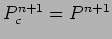

PRESSURE |

This option, which can take either value COLLOCATED or NONCOLLOCAED, specifies how to compute the

corrected pressure field. It is relevant only when ALGORITHM is set to A0, A4, A5, or A6.

|

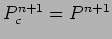

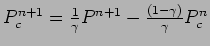

COLLOCATED

| In this case,  is set to the received pressure field is set to the received pressure field  (or (or  ), then converted to ), then converted to  before the aerodynamic forces are constructed and fed into the

structural equations of dynamic equilibrium (see the introduction to

this command). Therefore, this option covers the cases

before the aerodynamic forces are constructed and fed into the

structural equations of dynamic equilibrium (see the introduction to

this command). Therefore, this option covers the cases  and and  , which explains the origin of the word “collocated” (characters). , which explains the origin of the word “collocated” (characters).

|

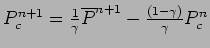

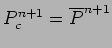

NONCOLLOCATED

| In this case, which is also the default value of PRESSURE, the pressure field  is set

to is set

to  (or (or  ), then converted to ), then converted to  (here, (here,  is the is the  parameter of the Generalized parameter of the Generalized  method). This specific choice for method). This specific choice for  is consistent with the quadrature rule of the Generalized is consistent with the quadrature rule of the Generalized  method for evaluating the work done by an external force in the time-interval method for evaluating the work done by an external force in the time-interval  . In other words, the pressure forces fed into the structural equations of equilibrium are based on . In other words, the pressure forces fed into the structural equations of equilibrium are based on  . For . For  , ,  , which explains the origin of the word “non collocated” (characters). , which explains the origin of the word “non collocated” (characters).

|

MATCHER |

|

pathandfilename

| Name (including path, if needed)

of the structural matcher file (characters). This file should be

specified because the fluid-structure computation is to be performed

without element deletion, using either the ALE or

EBM framework. In the first case, the structural mesh should be

matched with the fluid mesh. In the second case, it should be matched

with the embedded discrete surface and this surface should be inputted

to

AERO-F.

|

EMBEDDED [EMB] |

|

embeddedsurfaceid

| Integer identification number of a surface defined in SURFACETOPO

using 3-noded triangles, 4-noded quadrilaterals, or a combination of

such elements (integer). This parameter should be specified when the

discrete

surface to be embedded in the fluid mesh for the purpose of a

fluid-structure computation (with or without element deletion) is

identical to the wet surface of the finite element structural model and

defined using the same

nodes of this model. In this case, it is not necessary to specify

above a structure matcher file.

|

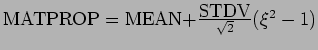

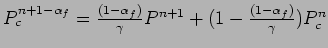

10 AEROHEAT

The AEROH command statement is used to indicate that AERO-S is to interact with AERO-F

to perform an aerothermal (thermostructure-thermofluid) coupled simulation, to select a staggered time-integration algorithm

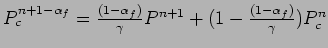

(ALGORITHM subcommand), and specify the  and

and  parameters of the following

prediction of the temperature of the structure at time-step

parameters of the following

prediction of the temperature of the structure at time-step  (

(ALGORITHM subcommand)

Note 1: Currently, the AEROH command supports only linear thermal analysis on the AERO-S side.

Note 2: The staggered solution algorithm A0 discussed below for aerothermal analysis requires the additional presence

in the input file containing this command statement of the DYNAMICS command in the dynamic case, or the QSTATICS

command in the static case.

Note 3: For a static aerothermal analysis, the staggered solution algorithm A0 must be specified only for parsing

reasons, as QSTATICS has its own staggered (iterative) solution scheme.

The syntax for invoking this command is given below.

|

ALGORITHM

|

11 ATTRIBUTES *S*

|

Command Statement: ATTRIBUTES

|

The ATTRIBUTES command statement is used to label an

element with an attribute identification number for linear elastic

material

and/or geometric properties, a composite or orthotropic shell, or

anisotropic solid element attribute identification number,

a frame or fiber-angle attribute identification number if this element

has been defined as a composite or orthotropic shell or anisotropic

solid element,

and a hyper reduction coefficient when the mesh containing this element

is sampled for the purpose of hyper reduction.

The attribute identification number for linear elastic material

properties and/or geometric properties is required for all elements

of the computational model. It is used in the MATERIAL command when specifying the linear elastic material properties

and/or geometric properties of a group of elements (see MATERIAL).

An “empty” (or “phantom”) element — that is, an element with zero generalized stiffness and mass matrices — can be useful

in aeroelastic and aerothermal computations to facilitate the exchange of elastodynamic, thermal, and aerodynamic

data between the fluid, thermal, and structural analyzers. Such an element can be specified by assigning it a negative

attribute number. In this case, it is not necessary to specify a material for such an element as its properties will be ignored.

It is also not necessary to assign an attribute number to a massless rigid element or simple joint element (types 118–125 and

127) for which the default constraint method (see CONSTRAINTS) is to be used for enforcing the associated constraints.

On the other hand, an attribute number should always be assigned to a rigid element which has a mass (see MATERIAL),

and a revolute-joint-with-joint-driver element (type 126) or a joint spring combination element (types 220–227), regardless of

whether the default constraint method is to be used or not for this element.

The hyper reduction coefficients are computed by the RMSHC command and outputted in the result file SAMPLMSH (see OUTPUT)

which includes the header ATTRIBUTES. Hence, this file can be simply included in the AERO-S input file using the

INCLUDE command (see INTRODUCTION) for the purpose of hyper reduction. An alternative approach for this purpose that leads

to faster CPU performance is to use the reduced mesh generated by the command RMSHC and outputted in the file SAMPLMSH.elementmesh.inc

(see OUTPUT).

AERO-S supports three input formats for this command that are described below.

In the case of the first format, there should be as many lines as the number of finite elements. All formats can be mixed.

Note 1: This command is required in any AERO-S ASCII Input Command Data file.

Note 2: Only the following element types can be used as “empty”

(or “phantom”) elements and therefore can be assigned negative attribute

numbers:

types 6 and 7 (beam elements); types 8, 88, 15, 1515, 16, 20, and 2020

(shell elements); types 19, 87, 128, and 129 (membrane elements); and

types 46 and 49 (thermal elements).

Note 3: When phantom elements are used in the mesh, the FETI solvers

are not guaranteed to work because of issues related to subdomain singularities.

Hence, it is not recommended to use FETI solvers in such cases.

Note 4: Phantom elements should be used with care to avoid the

generation of degrees of freedom without stiffness (and mass) and

therefore avoid introducing artificial singularities in the solution of

the problem of interest. In particular, it is strongly recommended to

ensure that every

node of every phantom element is also a node of a non-phantom element,

and that every local degree of freedom of a phantom element is also a

local degree

of freedom of a non-phantom element. In other words, it is strongly

recommended, for example, to avoid connecting a phantom shell element to

a face of a solid (brick element) and use instead

a phantom three-dimensional plane stress/plane strain element in this

case.

Note 5: Only phantom shell elements and phantom plane stress/plane strain elements can transfer aeroelastic loads to a structure.

Note 6: If an element is attributed two different material laws using the MATUSAGE/MATLAW and

ATTRIBUTES/MATERIAL commands, the material law defined in MATLAW and assigned in MATUSAGE takes precedence.

ELEMENT# MAT_ATT# CMP_ATT# CMP_FRM# HRC HRCOEFF [EXTFOL]

|

or

ELEMENT# MAT_ATT# CMP_ATT# THETA  HRC HRCOEFF [EXTFOL]

|

or

STARTING_ELEMENT# ENDING_ELEMENT# MAT_ATT# CMP_ATT# CMP_FRM#

|

or

STARTING_ELEMENT# ENDING_ELEMENT# MAT_ATT# CMP_ATT# THETA

|

or

STARTING_ELEMENT# ENDING_ELEMENT# IDENTITY

|

or

ELEMENT# HRC HRCCOEFF [EXTFOL]

|

ELEMENT#

| Element number whose attribute numbers are to be specified (integer).

|

MAT_ATT#

| Group identification number (integer); AERO-S supports gaps in numbering. Identifies material properties.

|

CMP_ATT#

| Composite (orthotropic or anisotropic) identification number (integer); AERO-S

supports gaps in numbering. Identifies composite (orthotropic or

anisotropic) properties.

May be left blank if element is not a composite (orthotropic or

anisotropic) element and must be set to -1 if the orthotropic and/or

anisotropic material properties of element are

specified using the command MATLAW instead of the command COMPOSITE.

|

CMP_FRM#

| Composite frame identification number (integer); AERO-S supports gaps in numbering. May be left blank if element is not a composite (orthotropic or

anisotropic) element.

|

THETA

| Keyword that must be spelled as THETA (characters). This keyword announces that the next item on the same

input line is the value  of of THETA. This unusual AERO-S input is necessary to avoid

parsing conflicts.

|

|

Reference angle in degrees between the axis defined by local

nodes 1 and 2 of the element, and the material local x-axis

defining the direction of the  and and  of the constitutive law (real).

When also using the of the constitutive law (real).

When also using the LAYN and LAYC commands, the material x-axis corresponds to the direction of  when when

is zero. If this angle rather than is zero. If this angle rather than CMP_FRM# is specified, the composite frame is internally generated by AERO-S.

|

STARTING_ELEMENT#

| First element of a sequence of elements that have the same MAT_ATT#, CMP_ATT#, and CMP_FRM# (integer).

|

ENDING_ELEMENT#

| Last element of a sequence of elements that have the same MAT_ATT#, CMP_ATT#, and CMP_FRM# (integer).

|

MAT_ATT#

| Group identification number. Identifies material properties (integer).

|

CMP_ATT#

| Composite identification number (integer). Identifies composite (orthotropic or anisotropic) properties.

May be left blank if element is not a composite (orthotropic or anisotropic) element.

|

CMP_FRM#

| Composite frame identification number (integer).

May be left blank if element is not a composite (orthotropic or anisotropic) element.

|

IDENTITY

| This keyword signals to the AERO-S code that each element in the range delimited

by STARTING_ELEMENT# and ENDING_ELEMENT# has a material attribute identification

number equal to its element identification number. For example, the sequence 1 3 IDENTITY

means that element#1 has the material attribute identification 1, element#2 has the material attribute identification 2,

and element#3 has the material attribute identification 3.

|

HRC

| Sub-command keyword to request

the application of a specified hyper reduction coefficient to the

element-level reduced internal forces and moments and acquiring this

coefficient (characters).

|

HRCOEFF

| Hyper reduction coefficient computed by the RMSHC command and stored in the result file SAMPLMSH under OUTPUT (float).

|

[EXTFOL]

| Optional sub-command keyword to

request the application of the specified hyper reduction coefficient to

all of the element-level reduced internal forces and moments and the

element-level reduced follower external forces and moments

(see FORCES) (characters).

|

12 BEAM OFFSET

|

Command Statement: BOFFSET

|

The BOFFSET command statement is used to specify a beam's neutral axis

offset from the line passing through its two end nodes. This command may

be used for both Euler-Bernoulli and Timoshenko beam elements. For beam

elements not listed under BOFFSET, a zero offset is used. If the BOFFSET

command is absent altogether, then an offset of zero is used for all beam

elements. If a listed element is neither an Euler-Bernoulli nor a

Timoshenko beam element, then the offset is ignored for that element.

The input format is as follows.

STARTING_ELEMENT# ENDING_ELEMENT# x y z

|

STARTING_ELEMENT#

| First element of a sequence of elements that have the same offset specified by {x, y, z} (integer).

|

ENDING_ELEMENT#

| Last element of a sequence of elements that have the same offset specified by {x, y, z} (integer). If ENDING_ELEMENT# is the same as STARTING_ELEMENT#, then the specified offset is applied to that element only (integer).

|

x

| x component of the offset vector expressed in the global frame (float).

|

y

| y component of the offset vector expressed in the global frame (float).

|

z

| z component of the offset vector expressed in the global frame (float).

|

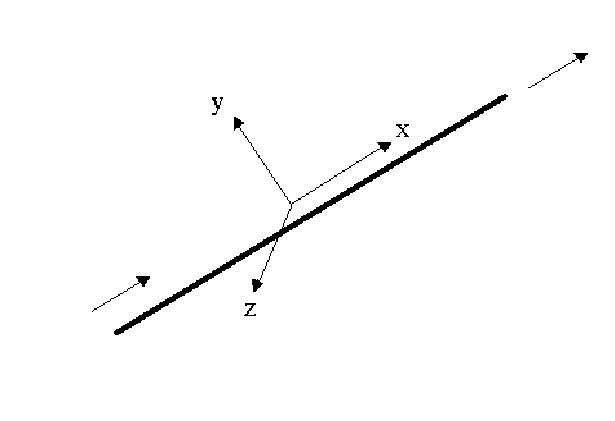

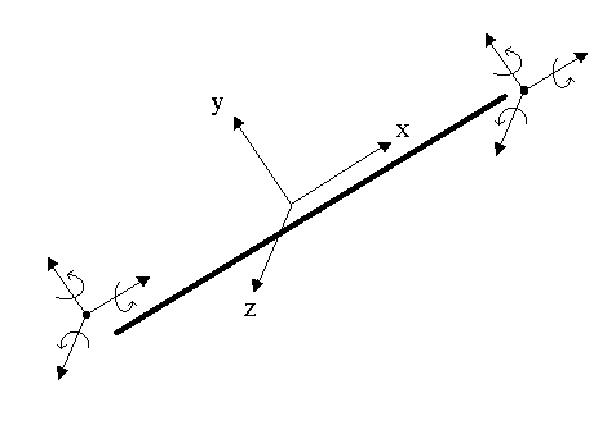

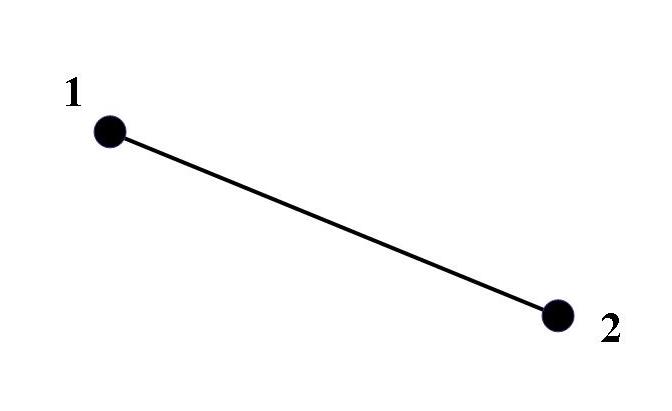

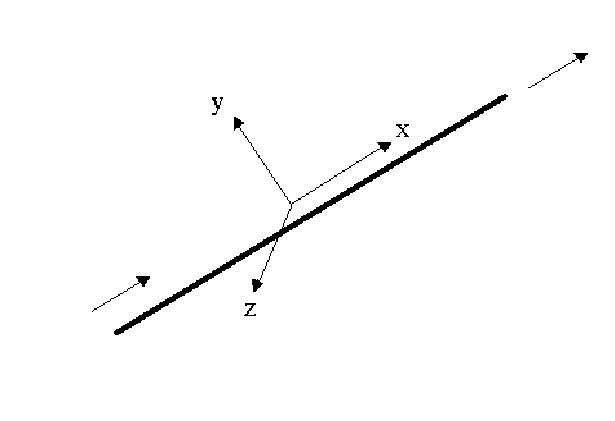

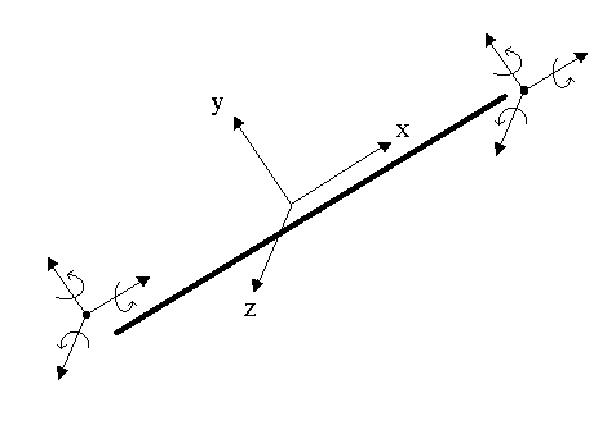

13 BEAM REFERENCE FRAMES

|

Command Statement: EFRAMES

|

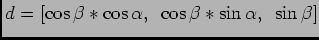

The EFRAMES command statement is used to specify a beam's orientation which defines the position of the beam

with respect to the global frame. The requirements for each beam frame are that one of the axis, the local x-axis, concurs with the longitudinal axis of

the beam, and the remaining two axes complete an orthogonal triad. If this requirement is violated, AERO-S regenerates the local x-axis

as well as the local z-axis.

For flexible beams, AERO-S also supports a run-time

generation of frames that is activated either when the target

flexible beam element is identified under this command and a third node

is specified to generate the frame, or when a third node is

found in the definition of a flexible beam element within the TOPOLOGY command. The only requirement for the third node is

that it does not be colinear with the other two beam nodes that define the local x-axis (X). Under this command, the third node

defines the X,Y plane. Under the TOPOLOGY command, it defines the X,Z plane. Using the third node option under

the TOPOLOGY command also relieves the user from specifying the EFRAMES command. An example illustrating the

third node option in the TOPOLOGY command can be found in FEM.d/fem_examples/Third_Node.d

Otherwise, the input format for this command is given below with the number of lines equal to the

number of beams in the problem.

or

ELEMENT# THIRDNODE third_node

|

Note 1: The above axes have to be normalized.

By default, the beam frames concur with the global frame.

14 BINARY INPUT / OUTPUT

|

Command Statement: BINARY

|

When the finite element model of interest is very large, it may

become necessary (for example, because of memory limitations), to

organize the input data of an AERO-S

computation in a set of binary distributed files, and more efficient to

output its results in another set of binary distributed files. This

requires:

- Using a version of aeros that is compiled in the distributed memory execution mode.

- Generating and using a mesh partition for the target simulation.

- Generating the binary distributed input files associated with the above mesh partition, as explained below.

- Inputting these binary distributed input files and if desired requesting the binary distributed format for the

output files, using the command

BINARY explained herein.

To decompose the input data contained in an initial instance of the ASCII Input Command Data file according

to a generated mesh partition and reorganize it in a set of binary distributed input files, the user

should use the specialized version of the software SOWER that is embedded in AERO-S.

The generated binary distributed input files can then be inputted via

this command in the final instance of the ASCII Input Command Data file.

This command can also be used to request outputting the results marked

for output in OUTPUT and/or OUTPUT6 in the binary distributed format

compatible with the generated mesh partition. In that case, the original SOWER (see SOWER's User's Reference Manual)

should be used to convert these output files into the ASCII format suitable for postprocessing by XPost.

If memory is not an issue, AERO-S can also operate directly on the global set of input data — that is,

on the standard content of the ASCII Input Command Data file.

Note 1: If aeros is not compiled in the distributed memory execution mode, it can only generate ASCII output files.

Most of these are in a format that is suitable for postprocessing by the XPost software, but some are in a format

that is suitable for postprocessing by gnuplot.

Note 2: Any command present in the initial instance of the

ASCII Input Command Data file and whose description in this User's

Reference Manual is marked by "*S*"

can be assumed to be contained in one of the aforementioned binary

distributed input files. However, if that command contains both an

algorithmic parameter as well as data,

only the data will be contained in the appropriate distributed binary

input file. Therefore, the command itself should be kept in

the updated ASCII Input Command Data file together with the algorithmic

parameter, but without the data. For example, the command

IDISPLACEMENTS specifies both an amplification factor and an initial displacement data.

The initial displacement data will be included in the aforementioned binary distributed input file, but the amplification

factor will not. This is to allow the user to change simple things such as this amplification factor without

having to regenerate the binary distribtued input files.

Note 3: This data organization option does not support the sparse direct solver MUMPS (see STATICS).

The syntax for this command is as follows.

BINARYINPUT | flagBIN | [<pathandfileprefix>]

| BINARYOUTPUT | flagBOUT

| CPUMAP | <pathandfilename>

|

|

BINARYINPUT flagBIN

| This pair of sub-command keyword (characters) and corresponding value (characters) can be used to choose between reading

the binary distributed input files designated by <pathandfileprefix>, or the standard ASCII global input data contained in the initial instance of the

ASCII Input Command Data file. flagBIN should be inputted on the same line as BINARYINPUT; it can take one of the following values:

|

On

| This setting chooses the specified binary distributed input files as input.

In this case, the user should check first that all binary distributed input files have been generated and that the

associated filenames and path are those referred to in <pathandfileprefix>.

|

Off

| This setting, which is also

the default setting, chooses the standard ASCII global data.

In this case, the user should check first that all needed

input data is included in the ASCII Input Command Data file.

|

<pathandfileprefix>

| This entry is relevant only when flagBIN is set to On. By default, AERO-S expects the binary input data command to be contained in four binary

distributed files named INPUT.dec, INPUT.con, INPUT.sub, and INPUT.msh.

Alternatively, this data can be contained in four equivalent files that are named differently, as long as they share

the same path and filename prefix — that is, these four binary distributed files must have the same path and can be

named fileprefix.dec (substitute for INPUT.dec), fileprefix.con (substitute for

INPUT.con), fileprefix.sub (substitute for INPUT.sub), and prefixfile.msh

(substitute for INPUT.msh). In the latter case, <pathandfileprefix> specifies the common filename prefix

(and file path if needed) (characters).

|

BINARYOUTPUT flagBOUT

| This pair of sub-command keyword (characters) and corresponding value (characters) can be used to choose between

outputting the results specified in OUTPUT and/or OUTPUT6 in the binary distributed format, or the standard ASCII global format.

flagBOUT should be inputted on the same line as BINARYOUTPUT; it can take one of the following values:

|

On

| This setting chooses the binary distributed format for all output files that support it.

|

Off

| This setting, which is also the default setting, chooses the standard ASCII global format for all output files.

|

CPUMAP <pathandfilename>

| This pair of sub-command

keyword (characters) and corresponding value (characters) can be used to

input a CPU map file – that is, a file that specifies to which CPU each

subdomain is to be assigned.

The format of this file is the same as that of the decomposition

file, with the number of subdomains replaced by the number of CPUs, the

number of elements in a given subdomain replaced by the number of

subdomains in a

given CPU, and the element ID number in each subdomain replaced by

the subdomain ID number in each CPU. The default for <pathandfilename> is CPUMAP, in which case this file must be located in the directory

where the simulation is launched. If <pathandfilename>

is not specified and a file named CPUMAP is not found in the

aforementioned directory, a default subdomain-to-CPU map is internally

generated by

AERO-S.

|

15 BOUNDARY CONVECTION *S*

Command Statement: CONVECTION [LOADSET_ID]

|

The CONVECTION command statement is used to specify

nodal convection type boundary conditions. Each node can have only

one degree of freedom. This command statement can be used

to solve a prescribed boundary convection problem for both statics and

dynamics. The input format is given below.

Note 1: This command contributes to the construction of the right-hand side

vector only. For the left-hand side (stiffness matrix) contribution,

AERO-S uses boundary convection elements and

information specified in the MATERIAL command.

LOADSET_ID

| Optional non-negative integer

which identifies explicitly the "load" set to which the source term

generated by this command belongs to (integer).

The default value is 0. Hence, the CONVECTION command can be repeated as many times as desired within the same input file using

each time a different value for LOADSET_ID and different data. The LOADCASE command can refer to LOADSET_ID to define one or multiple "load" cases

for static analysis (see the STATICS command and the explanation of its sub-command keyword CASES), and/or the "load" case for dynamic analysis.

|

NODE#

| Node number where the convection is specified (integer).

|

H_COEFF

| Convection coefficient at the prescribed node (float).

|

AREA

| Value of the node cross-sectional area (float).

|

TA

| Ambient temperature around the node (float).

|

16 BOUNDARY DISPLACEMENTS *S*

|

Command Statement: DISPLACEMENTS

|

The DISPLACEMENTS command is used to prescribe nodal displacements and/or rotations, either directly,

or via the definition of a surface using the command SURFACETOPO. In the latter case,

the specified displacement or rotation is applied to each specified local degree of freedom of each node of that surface.

The user can specify up to three displacements per node if a node can have up to three degrees of freedom,

and up to three displacements and three rotations if it can have up to six degrees of freedom.

Note 1: All degrees of freedom referred to by this command are

defined in the nodal degree of freedom reference frames defined at the

nodes

where these degrees of freedom are attached (see NODES and NFRAMES). By default, the nodal degree of freedom reference frames are the same

as the global reference frame.

Note 2: This command can also be used to specify nodal Dirichlet boundary conditions for a time-domain

of frequency-domain acoustic simulation by setting DOF# to 8 (see below). Hence, it can also serve as an alternative

to the ATDDIR and HDIR commands.

Note 3: In the context of a linearized (perturbation) analysis, the displacements boundary conditions specified under this

command are interpreted as displacement boundary perturbations.

Note 4: When the analysis is performed in the complex plane — for

example, in a frequency response analysis of a damped system — this

command can be used to prescribe only the real part of nodal

displacements and/or rotations, as in this case it automatically sets

their

imaginary part to zero.

The following two formats are available for this command and can be mixed.

SURFACE SURFACE# DOF# VALUE

|

NODE#

| Node number where the displacement or rotation is specified (integer).

|

DOF#

| Degree of freedom local number where the displacement or rotation is specified (integer).

|

VALUE

| Value of the specified displacement or rotation (real).

|

SURFACE

| Keyword indicating that a surface defined in SURFACETOPO is to be identified next by its integer identification number (characters).

|

SURFACE#

| Integer identification of the surface defined in SURFACETOPO where the force VALUE is specified (integer).

|

17 BOUNDARY FLUXES

Command Statement: FLUX [LOADSET_ID]

|

The FLUX command statement is used to specify nodal heat sources (for example, products of nodal

areas and nodal values of finite element fluxes) either directly, or via the definition of a surface using

the command SURFACETOPO. In the latter case,

a specified heat source is applied to each node of the identified surface.

This command statement can be used to define both statics and dynamics heat problems with prescribed

temperature flux boundary conditions.

Its input format is given below.

LOADSET_ID

| Optional non-negative integer

which identifies explicitly the "load" set to which the source term

generated by this command belongs to (integer).

The default value is 0. Hence, the FLUXES command can be repeated as many times as desired within the same input file using

each time a different value for LOADSET_ID and different data. The LOADCASE command can refer to LOADSET_ID to define one or multiple "load" cases

for static analysis (see the STATICS command and the explanation of its sub-command keyword CASES), and/or the "load" case for dynamic analysis.

|

NODE#

| Node number where the flux is specified (integer).

|

VALUE

| Value of the prescribed boundary flux (float).

|

SURFACE

| Keyword indicating that a surface defined in SURFACETOPO is to be identified next by its integer identification number (characters).

|

SURFACE#

| Integer identification of the surface defined in SURFACETOPO where the nodal heat source VALUE is specified (integer).

|

18 BOUNDARY FORCES *S*

Command Statement: FORCES [LOADSET_ID]

|

The FORCES command is used to prescribe external nodal forces and/or moments, either directly,

or via the definition of a surface using the SURFACETOPO command. In the latter case,

the specified force or moment is applied to each specified local degree of freedom of each node of that surface.

The user can specify up to three forces per node if a node has three degrees of freedom attached to it,

and up to three forces and three moments if it has six degrees of freedom attached to it.

By default, all prescribed forces and moments are interpreted as being of the axial type — that is, as being

defined in the fixed nodal degree of freedom reference frames (see NODES and NFRAMES).

However, if a node has rotational degrees of freedom, the user

can specify that the forces and/or moments prescribed at this node

are of the follower type — that is, they act in a direction that remains constant in the local frame attached to the node

where they are applied. This local frame coincides with the nodal degree of freedom reference frame

(see NODES and NFRAMES) in the undeformed configuration. In the deformed configuration, the orientation of

this local frame is defined by the rotation of the node to which it is attached. In other words, the specified

nodal force or moment "follows" in this case the rotation of the node to which it is applied.

Finally, the user can also time-vary the specified forces and moments using the MFTT command.

Note 1: By default, the nodal degree of freedom reference frames are the same as the global reference frame.

Note 2: This command can also be used to specify nodal Neumann boundary conditions for a time-domain acoustic

simulation by setting DOF# to 8 (see below). Hence, it can also serve as an alternative to the ATDNEU

command (see ATDNEU).

Note 3: Specifying a follower force or moment leads to an unsymmetric tangent "load" stiffness matrix during

a NONLINEAR analysis.

The following two formats are available for this command and can be mixed.

NODE# | DOF# | VALUE | TYPE |

| SURFACE | SURFACE# | DOF# | VALUE | TYPE

|

|

LOADSET_ID

| Optional non-negative integer

which identifies explicitly the "load" set to which the source term

generated by this command belongs to (integer).

The default value is 0. Hence, the FORCES command can be repeated as many times as desired within the same input file using

each time a different value for LOADSET_ID and different data. The LOADCASE command can refer to LOADSET_ID to define one or multiple "load" cases

for static analysis (see the STATICS command and the explanation of its sub-command keyword CASES), and/or the "load" case for dynamic analysis.

|

NODE#

| Node number where the force or moment is specified (integer).

|

DOF#

| Degree of freedom local number where the force or rotation is specified (integer).

|

VALUE

| Value of the specified force or moment (real).

|

TYPE

| By default, all specified nodal forces and moments are considered to be of the axial type. However, if this parameter

is set to FOLLOWER and the node where a force or moment is specified has rotational degrees of freedom, this

specified nodal force or moment is considered to be of the follower type (characters).

|

SURFACE

| Keyword indicating that a surface defined in SURFACETOPO is to be identified next by its integer identification number (characters).

|

SURFACE#

| Integer identification of the surface defined in SURFACETOPO where the force or moment VALUE is specified (integer).

|

19 BOUNDARY TEMPERATURES *S*

|

Command Statement: TEMPERATURES

|

The TEMPERATURES command statement is used to specify prescribed

nodal temperature type boundary conditions either directly, or via the definition of a surface using the command SURFACETOPO.

In the latter case, a specified temperature is applied to each node of the identified surface.

For structural analysis using AERO-S, this command statement

causes AERO-S to construct

a thermal load based on the prescribed nodal temperatures and the reference temperatures

(see MATLAW, see TOPOLOGY, and use this load as usual in a structural analysis).

Note 1: The default value of a nodal temperature is the reference temperature Ta of the element containing this node (see MATERIAL).

The input format of this command is given below.

NODE#

| Node number where the temperature is specified (integer).

|

VALUE

| Value of the prescribed temperature (float).

|

SURFACE

| Keyword indicating that a surface defined in SURFACETOPO is to be identified next by its integer identification number (characters).

|

SURFACE#

| Integer identification of the surface defined in SURFACETOPO where the temperature VALUE is specified (integer).

|

20 BUCKLING

|

Command Statement: BUCKLE

|

The BUCKLE command statement is to be used together with the GEPS, IDISP6 (with  ),

and

),

and EIGEN command statements to request the buckling analysis of a given

structure.

When the EIGEN, GEPS, and IDISP6 (with  ) command statements are specified in

the input file, the

) command statements are specified in

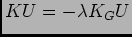

the input file, the BUCKLE command statement signals to FEM that the eigenvalue

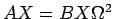

problem to be solved is  , where

, where  is the geometric